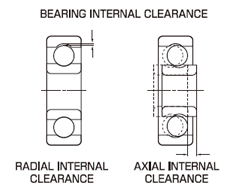

Bearing internal clearance

INTERNAL CLEARANCE AND STANDARD VALUES

Internal clearance is the play between outer ring, inner ring and rolling element. Generally, the amount of up and down movement of the outer ring with respect to the fixed inner ring is called the radial internal clearance and its right and left movement the axial internal clearance. Bearing internal clearance in operation is an important factor that has a significant influence on other factors such as noise, vibration, heat and fatigue life. Radial ball bearings are usually classified by their internal radial clearance. When measuring the internal clearance, the bearing is subjected to a standard load in order to ensure full contact between all bearing components. Under such a load, the measured value is larger than the actual value stated for radial clearance; this is due to elastic deformation. The difference is compensated by the factors given in the tables below.

RADIAL INTERNAL CLEARANCE OF SMALL AND MINIATURE BEARINGS

| CLEARANCE SYMBOL | MC1 | MC2 | MC3 | MC4 | MC5 | MC6 | |

|---|---|---|---|---|---|---|---|

| CLEARANCE | min. | 0 | 3 | 5 | 8 | 13 | 20 |

| max. | 5 | 8 | 10 | 13 | 20 | 28 | |

Unit μm

note:

1. standard clearance is MC3.

2. for measuring clearance, offset by compensation factor listed below

| CLEARANCE SYMBOL | MC1 | MC2 | MC3 | MC4 | MC5 | MC6 |

|---|---|---|---|---|---|---|

| COMPENSATION FACTOR | 1 | 1 | 1 | 1 | 2 | 2 |

MEASURING LOAD IS AS FOLLOWS:

MINIATURE BEARING 2.5N (0.25kgf )

SMALL SIZE BEARINGS 4.4N (0.45kgf )

RADIAL INTERNAL CLEARANCE OF STANDARD RADIAL BALL BEARINGS

| NOMINAL BORE DIAMETER d(mm) | CLERANCE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C2 | CN(C0) | C3 | C4 | C5 | |||||||

| OVER | INCL. | MIN | MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | MAX |

| 10(ONLY) | 0 | 7 | 2 | 13 | 8 | 23 | 14 | 29 | 20 | 37 | |

| 10 | 18 | 0 | 9 | 3 | 18 | 11 | 25 | 18 | 33 | 25 | 45 |

| 18 | 24 | 0 | 10 | 5 | 20 | 13 | 28 | 20 | 36 | 28 | 48 |

| 24 | 30 | 1 | 11 | 5 | 20 | 13 | 28 | 23 | 41 | 30 | 53 |

| 30 | 40 | 1 | 11 | 6 | 20 | 15 | 33 | 28 | 46 | 40 | 64 |

| 40 | 50 | 1 | 11 | 6 | 23 | 18 | 36 | 30 | 51 | 45 | 73 |

Unit μm

note:

1. For measuring clearance, offset by compensation factor listed below.

| BORE DIAMETER OF NOMINAL BEARING d(mm) | MEASURING LOAD | COMPENSATION FACTOR | |||||

|---|---|---|---|---|---|---|---|

| OVER | INCL. | N (kgf) | C2 | CN (C0) | C3 | C4 | C5 |

| 10(INCLUDED) | 18 | 24.5 (2.5) | 3~4 | 4 | 4 | 4 | 4 |

| 18 | 50 | 49 (5) | 4~5 | 6 | 6 | 6 | 6 |

Unità di misura μm

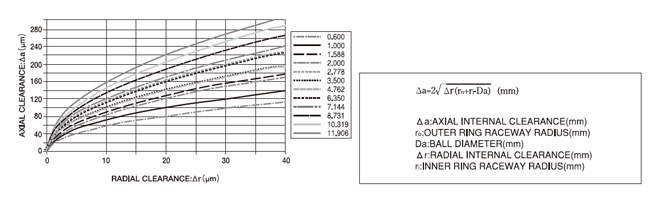

RELATIONSHIP BETWEEN RADIAL INTERNAL CLEARANCE AND AXIAL INTERNAL CLEARANCE

The axial internal clearance is established from the ball diameter, outer and inner ring raceway radius and the radial internal clearance. Usually it is about 10 times the value of the internal radial clearance. Selection of a small internal radial clearance or an extra large interference fit in order to reduce the internal axial clearance after mounting is not recommended.

SELECTION OF BEARING CLEARANCE

Theoretically, maximum bearing life is with very slight preload. However, even a slight increase in this theoretical preload can have a considerably detrimental effect on the bearing life. Positive clearance should therefore be selected. MC3 is usually used for miniature or small bearings, standard clearance for general bearings and the clearance for thin section bearings should never be greater than "standard".

SELECTION OF RADIAL INTERNAL CLEARANCE

| OPERATING CONDITION | CLEARANCE |

|---|---|

|

Clearance fit for inner and outer ring. Low axial load. No axial load carrying requirement. Select bearing with reduced radial clearance. Lower vibration and noise. Low speeds. |

MC1, MC2, C2 |

| Lower frictional torque. Standard axial load. Average axial load carrying requirements. Slight interference fit for inner ring. Clearance fit for outer ring. Average/low speeds. | MC3, MC4, CN(C0) |

| Extremely low frictional torque. High axial load. High axial load carrying requirements. Heavy interfence fit to support high loads or shock loads. Large temperature gradient from inner ring to outer ring. High degree of shaft deflection. | MC5, MC6, C3, C4, C5 |

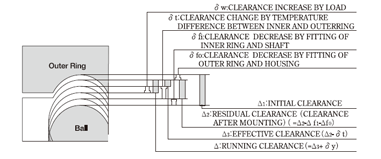

CALCULATION OF CLEARANCE

1) RUNNING CLEARANCE

Running clearance is the resultant clearance after load, temperature difference and fitting are taken into consideration.

2) CLEARANCE REDUCTION BY TEMPERATURE DIFFERENCE BETWEEN INNER AND OUTER RING

In a bearing, the highest temperature is generated in the rolling element followed by the inner ring, with the outer ring having the lowest temperature. Since it is impossible to measure the temperature of a rolling element, in practice, the temperature of the inner ring is used.

3) CLEARANCE REDUCTION BY FITTING

When a bearing is fitted onto a shaft or into a housing with an interference fit, the internal clearance of the bearing reduces.

∆ db×d/db×((1-(do/d)2))/(1-(do/db)2))+

∆ Da×Da/D×((1-D/Dh)2))/(1-(Da/Dh)2)) (mm)

4) CLEARANCE INCREASE BY LOAD

Load on a bearing deforms it elastically and increases the internal clearance.

The initial contact angle α is calculated from the follwing two formulae:

1-cos α 0 = ∆r/(2×DW×(2×m-1))

SYMBOLS

| ∆T | Temperature difference between inner and outer ring | m | Osculation |

| D0 | Outer ring raceway diameter | Z | Number of balls |

| ∆db | Clearance of inner ring on shaft | Dw | Ball diameter |

| d0 | Bore diameter of hollow shaft | α | Contact angle |

| Dn | Outside diameter of housing seat | α0 | Initial contact angle |

| ∆Da | Clearance of outer ring in housing | Fa | Axial load |

| db | Average outside diameter of inner ring | Fr | Radial load |

| Da | Average outside diameter of outer ring | ∆r | Radial internal clearance |

| a | Coefficent of thermal expansion for bearing steel | C | Material elesticity factor |

| General Bearing | C=0.00218 | m=0.525 |

|---|---|---|

| Instrument Bearing | C=0.00287 | m=0.560 |